Super Economical Reusable CNC Molybdenum Wire Cutting EDM Machine Dk7750

Product Details:

| Place of Origin: | China |

| Brand Name: | TOSUN |

| Certification: | CE |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Wooden Case |

| Delivery Time: | Peak Season Lead Time: within 15 workdays, Off Season Lead Time: within 15 workdays |

| Payment Terms: | LC, T/T, D/P, PayPal, Western Union, Small-amount payment |

| Supply Ability: | 1000PCS/Year |

|

Detail Information |

|||

| Model NO.: | SE500 | Numerical Control: | CNC/MNC |

|---|---|---|---|

| Processing Precision: | 0.01~0.02(mm) | Performance Classification: | Economical CNC Machine Tools |

| Condition: | New | Transport Package: | Wooden Case |

| Specification: | 2070x1850x2100 | Trademark: | TOSUN |

| Origin: | Suzhou | HS Code: | 8456301090 |

| Supply Ability: | 1000PCS/Year | After-sales Service: | Yes |

| Warranty: | 1 Year | Application: | Metal |

| Process Usage: | Metal-Cutting CNC Machine Tools | Movement Method: | Linear Control |

| Control Method: | Open-Loop Control | Customization: | Available | Customized Request |

Product Description

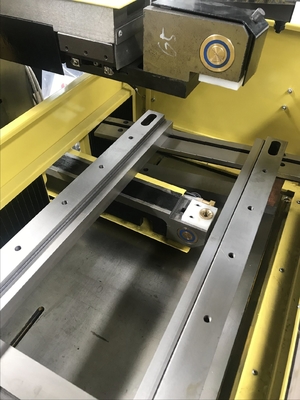

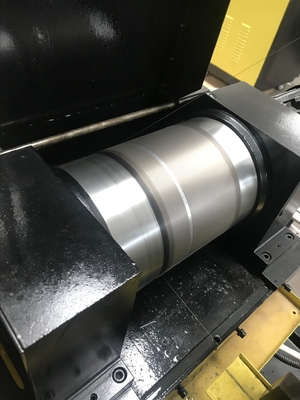

CNC Molybdenum Wire Cutting EDM Machine (Super Economical) DK7750 is a special machine designed for mass and high efficiency processing. The machine has high efficiency, high processing accuracy, good smoothness of multiple cutting, simple operations, and high consistency of machine tool processing. The machine is suitable for cutting work pieces in large quantities. Compared to similar machines, our SE500 offers a remarkable 5%-10% increase in processing efficiency, saving you valuable time and resources.

| No. | Description | Unit | Specification |

| 1 | Model | SE500 | |

| 2 | Worktable Size (L×W) | mm | 600x900 |

| 3 | Worktable Travel (X×Y) | mm | 550x800 |

| 4 | Max. Workpiece Height | mm | 600 |

| 5 | Max. Workpiece Weight | kg | 700 |

| 6 | Machine Dimensions (L×W×H) | mm | 2070x1850x2100 |

| 7 | Machine Weight | kg | 2500 |

Electrical Parameters

| No. | Description | Unit | Specification |

| 1 | Max. Cutting Speed | mm²/min | 180 |

| 2 | Wire Electrode Diameter | mm | Φ0.18~Φ0.25 |

| 3 | Machining Precision (Cutting the octagon) | mm | ≤0.012/10мм |

| 4 | Taper/Workpiece Height | 6°/100mm | |

| 5 | Power Consumption | kw | 3 |

| 6 | Surface roughness | μm | Single cut Ra<2.5 *Multi cut Ra<1.0 |

| 7 | High pressure water tank | Multi-stage filter system | |

| 8 | Plastic water jet plate; Bronze spout | ||

| 9 | Control method of Z-axis manual, transport wire tube, cooling system | Controlled by the program and the NC panel | |

| 10 | Repeating position precision of X, Y-axis | μm | ±1 |

| 11 | Guide rail type of U,V-axis | railroad rail | |

| 12 | Speed regulation of transport wire tube | Integrated frequency inverter | |

| 13 | Number of control axes | 5 | |

| 14 | Power Supply | AC380V, 50Hz |

![]()

![]()

![]()

![]()

![]()