Spark Working Wire Cutting CNC Machine D320c with Servo Motor and Electric Discharge

Product Details:

| Place of Origin: | China |

| Brand Name: | TOSUN |

| Certification: | ISO 9001 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Wooden Case |

| Delivery Time: | Peak Season Lead Time: within 15 workdays, Off Season Lead Time: within 15 workdays |

| Payment Terms: | LC, T/T, D/P, PayPal, Western Union, Small-amount payment |

| Supply Ability: | 1000PCS/Year |

|

Detail Information |

|||

| Model NO.: | D320C | Precision: | High Precision |

|---|---|---|---|

| Condition: | New | Transport Package: | Wooden Case |

| Specification: | 1680× 1200× 2300 | Trademark: | TOSUN |

| Origin: | Suzhou | HS Code: | 8456301090 |

| Supply Ability: | 1000PCS/Year | After-sales Service: | Online And Video Support |

| Warranty: | Yes | Type: | Wire Cutting |

| Application: | Metallurgy, Universal, Stainless Steel, Electrical, Aviation, Light Industry | Processing Method: | Spark Working |

| Automatic Grade: | Automatic | Customization: | Available | Customized Request |

Product Description

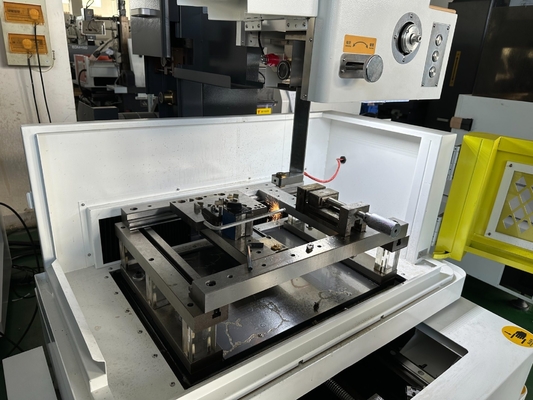

With its high position accuracy, processing accuracy, stable processing, and high consistency, this machine is perfect for the processing of precision molds like progressive dies.

At Jilin Songjiang Tech-trade Co., Ltd., we take pride in offering top-notch products that meet the needs of our customers. Our Servo Motor CNC Wire Cutting EDM Machine (Expert) D320C is no exception. With its advanced features and reliable performance, it's a game-changer in the industry.

Key Features:

- High rigidity cast iron C shape structure

- X/Y axis Panasonic AC servo Motor

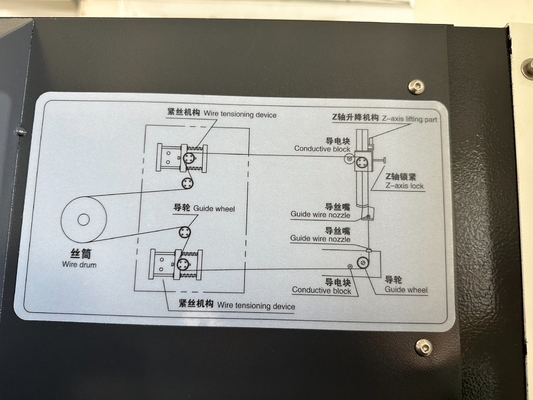

- Automatic tighting system

- Linear guide rail (HIWIN)

- Z axis auto lift funtion

- Intergrated electric lubrication system of guide rail and lead screw

- Industrial computer IPC

- Separating transformer system

- Speical Aluminum cutting device (optional)

| No. | Description | Unit | Specification |

| 1 | Model | D320C | |

| 2 | Worktable Size (L×W) | mm | 660×450 |

| 3 | Worktable Travel (X×Y) | mm | 320×400 |

| 4 | Max. Workpiece Height | mm | 300 |

| 5 | Max. Workpiece Weight | kg | 500 |

| 6 | Machine Dimensions (L×W×H) | mm | 1680×1200×2300 |

| 7 | Machine Weight | kg | 2000 |

| No. | Description | Unit | Specification |

| 1 | Max. cutting speed | mm²/min | ≥240 |

| 2 | Wire electrode diameter | mm | Φ0.08~Φ0.25 |

| 3 | Machining precision (Cutting the octagon in 10mm) | mm | ±0.003 |

| 4 | Taper/Workpiece height | *±6°/80mm | |

| 5 | Power consumption | kw | 3 |

| 6 | Surface roughness | μm | **Multiple cut Ra≤0.6 |

| 7 | High pressure water tank | Multi-stage filter system | |

| 8 | Wire guided spinneret | Ruby spinneret | |

| 9 | Control method of wire spool, cooling system | Controlled by the program and the NC panel | |

| 10 | Repeating position precision of X, Y-axis | μm | ±1 |

| 11 | Guide rail type | Linear guide rail | |

| 12 | Speed regulation of transport wire tube | Converter | |

| 13 | Number of control axes | 5 | |

| 14 | Power Supply | AC380V, 50Hz |

**The material of workpiece is Cr12 and the height is less than 100mm.

![]()

![]()

![]()

![]()

![]()