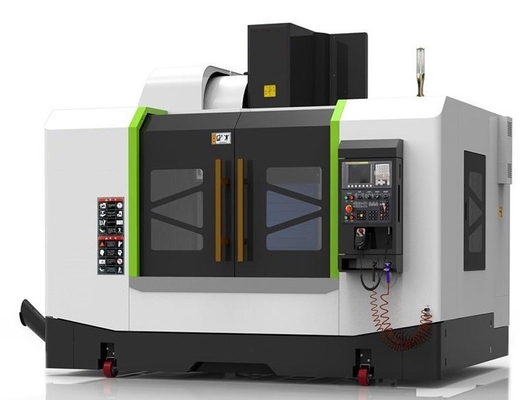

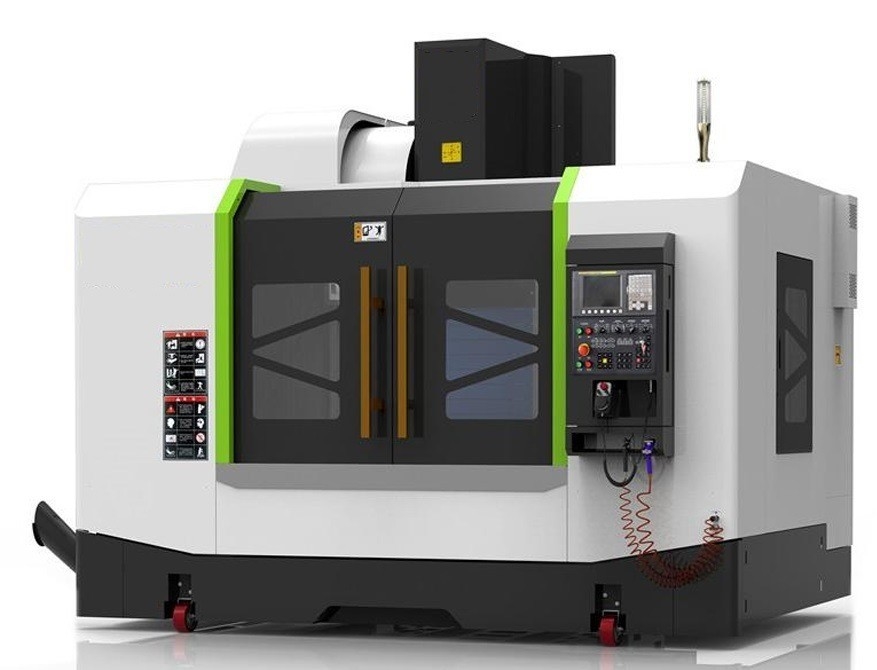

Customization CNC Vertical Milling Machine Vm540 with Fanuc Control System

Product Details:

| Place of Origin: | China |

| Brand Name: | TOSUN |

| Certification: | ISO 9001 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Wooden Case |

| Delivery Time: | Peak Season Lead Time: within 15 workdays, Off Season Lead Time: within 15 workdays |

| Payment Terms: | LC, T/T, D/P, PayPal, Western Union, Small-amount payment |

| Supply Ability: | 1000PCS/Year |

|

Detail Information |

|||

| Model NO.: | VM540 | Milling Cutter Structure: | Integral |

|---|---|---|---|

| Controlling Mode: | CNC | Automatic Grade: | Automatic |

| Precision: | High Precision | Condition: | New |

| Transport Package: | Wooden Case | Specification: | 2650× 2100× 2500mm |

| Trademark: | TOSUN | Origin: | China |

| HS Code: | 8457101000 | Supply Ability: | 1000PCS/Year |

| After-sales Service: | Online And Video Support | Warranty: | 1 Year |

| Type: | Worktable Milling Machine | Object: | Tool |

| Structure: | Bed Type | Milling Cutter Type: | Vertical Milling Cutter |

| Customization: | Available | Customized Request | ||

Product Description

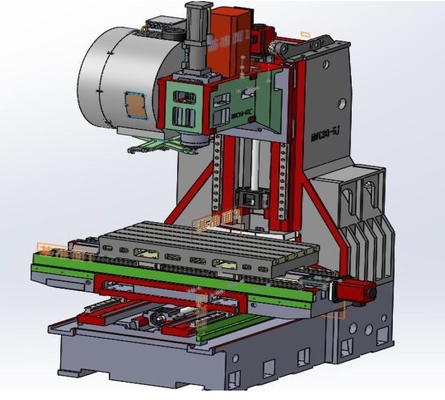

- The machine tool base, columns, spindle box, cross slide, and worktable are all made of high-strength lost foam casting technology. The internal metallographic structure is stable, ensuring the high stability of the basic parts. The casting structure has undergone machine tool dynamics analysis and finite element analysis to make its geometric structure more reasonable, and the appropriate matching with the reinforcing ribs ensures the high rigidity of the basic parts.

- Use high-rigidity and high-precision spindle from Taiwan KENTURN.

- Use high-precision and high-strength ball screws from Taiwan.

- The X, Y, and Z axes use Taiwan 45mm roller linear rails, and the slides are widened and enlarged. The roller heavy-duty linear rail can not only meet the customer's requirements for fast speed and high precision, but also can perform powerful cutting, while also increasing the service life.

- The machine is equipped with a sealed guide rail protective cover to effectively protect the guide rails and screws and extend their service life.

- The machine tool is equipped with three-dimensional full protection to ensure no vibration during strong chip cutting.

- Use Japanese Fanuc CNC operating system, paired with an absolute servo motor, ensuring high stability, fast speed, smooth surface, and high precision.

- Double-pump automatic lubrication system: The guide rail lubrication uses a volume distributor with oil injection to supply the oil required for the guide rail regularly and quantitatively, reducing the waste of lubricating oil. The water tank is equipped with an oil-water separator to avoid environmental pollution.

- High-precision pitch compensation. At the same time, advanced ballbar is used to optimize the accuracy when processing circles and curved surfaces.

| Item | Unit | Description | |

| Spindle | Spindle unit | BT40-120mm | |

| Speed | r/min | 50~8000 | |

| Spindle end face to worktable | mm | 120-520 | |

| Spindle center to column | mm | 460 | |

| Worktable | Worktable size | mm | 760×400 |

| T-slot number, width and spacing | mm | 5×18×80 | |

| Max. load | kg | 300 | |

| Guide rail | Guide rail type | Roller linear guide for X, Y, Z axis | |

| Guide rail width for X, Y, Z axis | mm | 35/35/35 | |

| Roller guide screw | X axis | mm | φ40×12 |

| Y axis | mm | φ40×12 | |

| Z axis | mm | φ40×12 | |

| Travel | X axis | mm | 600 |

| Y axis | mm | 400 | |

| Z axis | mm | 400 | |

| Fast moving speed | X axis | m/min | 24 |

| Y axis | m/min | 24 | |

| Z axis | m/min | 22 | |

| Cutting feed speed | m/min | 1-8000 | |

| Control system | Fanuc | ||

| Servo motor | Spindle motor | KW | 5.5 |

| X, Y axis servo motor | βis8/3000 | ||

| Z axis servo motor | Βis12/3000 | ||

| Positioning accuracy for X, Y, Z axis | mm | 300/±0.005 | |

| Repeatability accuracy for X, Y, Z axis | mm | 300/±0.003 | |

| Air pressure | MPa | 0.6-0.8 | |

| Machine weight | kg | 4600 | |

| Machine size(L×W×H) | mm | 2650×2100×2500mm | |

Equipment Configurations

| No. | Name | No. | Name |

| 1 | Spindle pneumatic loose broach | 8 | Z-direction stainless steel cover |

| 2 | Handheld air gun | 9 | Anchor bolts and pads |

| 3 | Automatic lubrication system | 10 | Cooling horizontal water pump 270W |

| 4 | LED warning light | 11 | Rigid tapping |

| 5 | Electrical box dustproof device | 12 | RS-232 interface and USB function |

| 6 | 24V work light | 13 | Power distribution box safety lock |

| 7 | XY guide rail stainless steel guard |

Component Manufacturer

| Item | Quantity | Manufacturer |

| Control system | 1 set | Fanuc |

| Spindle servo motor | 1 set | Fanuc |

| Spindle driver | 1 set | Fanuc |

| X, Y, Z axis servo motor | 1 set for each | Fanuc |

| X, Y, Z axis driver | 1 set for each | Fanuc |

| X, Y, Z axis screw bearing | 1 set for each | Japan NSK |

| X, Y, Z axis ball screw φ40×12 | 1 set for each | Taiwan |

| X, Y, Z axis roller rail 35mm | 1 set for each | Taiwan |

| Locking nut | 1 set | Taiwan |

| Spindle unit BT40-120mm | 1 set | Taiwan |

| Main pneumatic components | 1 set | Taiwan |

| Main electrical components | 1 set | Germany |

| Automatic lubrication system | 1 set | HERG |

| Synchronous pulley and synchronous belt | 1 set | Taiwan |

| Cutting fluid pump | 1 set | Changzhou |

| Electrical cabinet switch | 1 set | Tongfei |

| Cylinder 4.5T | 1 pc | Guoding |

| Electronic handwheel | 1 pc | Shanghai |

| Operation panel | 1 pc | Shanghai |

![]()

![]()

![]()

![]()

Want to Know more details about this product